How Are Plastic Bottles Made

Jan 18, 2026

The 2026 Guide to Manufacturing and rPET

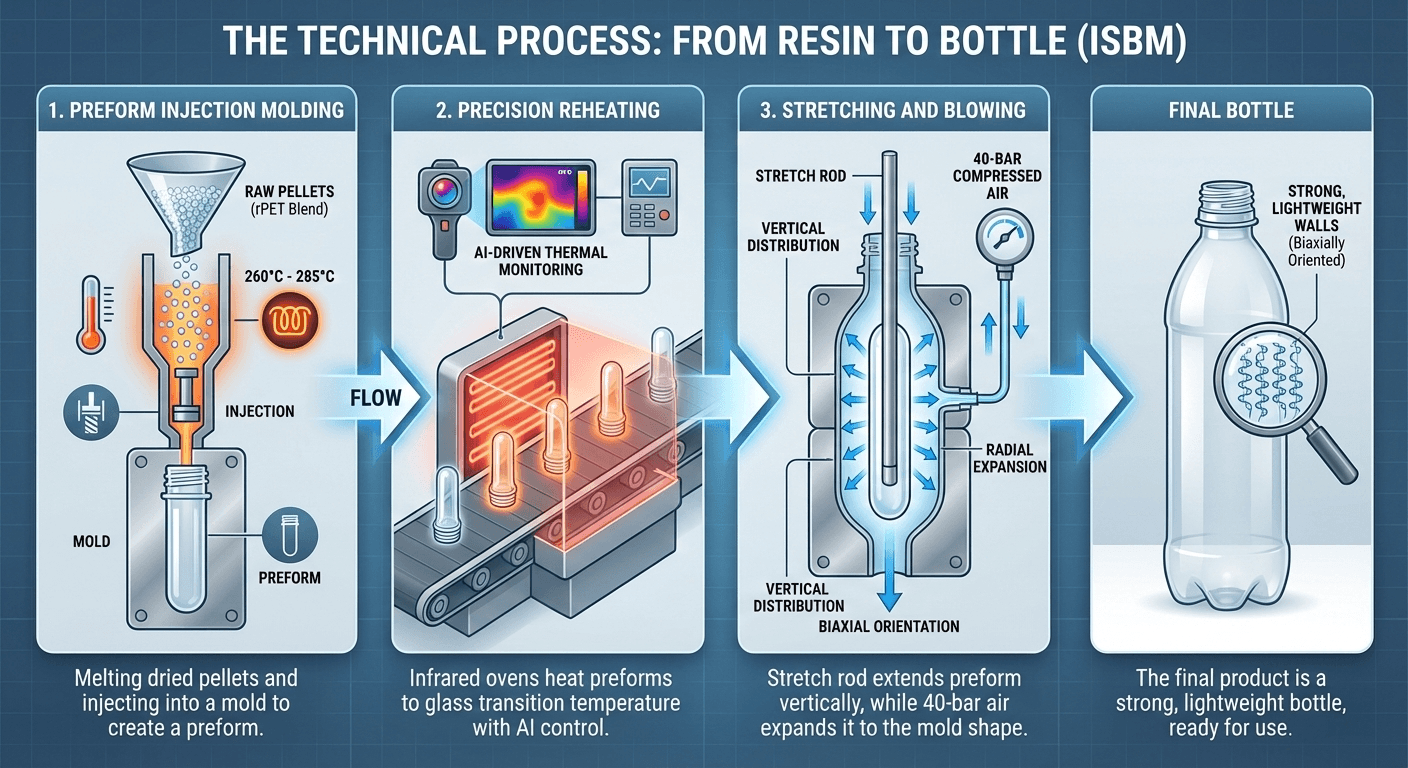

The Short Answer: Plastic bottles are primarily manufactured using a process called Injection Stretch Blow Molding (ISBM). This two-stage method begins by melting Polyethylene Terephthalate (PET) resin into a thick-walled preform. This preform is then reheated and inflated using 40-bar high-pressure air inside a mold to reach its final shape. In 2026, the industry has shifted toward 100% rPET (recycled plastic), where the manufacturing art lies in balancing structural integrity with the natural tints of recycled materials.

The Technical Process: From Resin to Bottle

To understand modern packaging, you have to look at the Injection Stretch Blow Molding (ISBM) method, which accounts for the vast majority of beverage containers worldwide.

1. Preform Injection Molding

The process starts with raw plastic pellets—increasingly a blend of mechanical and enzymatic rPET. These pellets are dried to prevent moisture-related defects and melted at temperatures between 260°C and 285°C. The molten plastic is injected into a mold to create a preform, which looks like a thick test tube with a pre-threaded neck.

2. Precision Reheating

Before blowing, the preforms travel through infrared ovens. In 2026, high-speed lines utilize AI-driven thermal monitoring to ensure the plastic reaches its glass transition temperature perfectly. If the heat is off by even a few degrees, the bottle will have uneven wall thickness or poor clarity.

3. Stretching and Blowing

The softened preform is placed into the final bottle mold. A stretch rod extends into the bottle to ensure vertical distribution, while a blast of 40-bar compressed air forces the plastic against the cold mold walls. This biaxial orientation is what gives a plastic bottle its incredible strength-to-weight ratio.

Comparing Manufacturing Methods: ISBM vs. Extrusion

While PET is the industry standard for drinks, other materials and shapes require different engineering approaches.

Manufacturing Method | Material Used | Primary Use Case | Technical Characteristic |

Stretch Blow (ISBM) | PET / rPET | Water, Soda, Personal Care | Uses a stretch rod for strength. |

Extrusion Blow (EBM) | HDPE / PP | Milk, Detergent, Shampoo | Features a visible seam on the bottom. |

Injection Molding | Various | Caps, Lids, Small Jars | Highest precision for threads. |

Why the Perfectly Clear Bottle is Disappearing

The definition of a perfect bottle has fundamentally changed. We used to spend millions on additives to achieve a crystal-clear, 'virgin' look, but 2026 has brought a reality check: Perfection is now a trust barrier. Research published in 2025 (ResearchGate) confirms that for modern shoppers, the 'Sustainable Material' claim carries more weight than visual clarity. Leading brands like Evian have successfully pioneered this shift, proving that a slightly tinted rPET bottle actually increases eco-trust. The tint serves as visual evidence that the material is truly recycled. Today, the art of manufacturing isn’t about hiding those natural grey or blue hues; it’s about using subtle toners to make that recycled tint look intentional and premium, a signal to the consumer that the bottle is part of a circular loop rather than a one-way trip to a landfill.

Frequently Asked Questions

What is the difference between virgin PET and rPET?

Virgin PET is made from petroleum-based feedstocks and is naturally crystal clear. rPET is made from post-consumer recycled waste. While rPET can have a slight tint, it reduces the carbon footprint of the bottle by up to 79%.

Why do some plastic bottles have a yellow or blue hue?

This is a result of the recycling process. Repeated heating cycles (thermal history) cause minor degradation. Many manufacturers now use color-neutralizing toners to ensure this tint looks premium.

Is 100% recycled plastic as strong as new plastic?

Yes, provided the Intrinsic Viscosity (IV) is managed correctly during the injection phase. Modern additives and AI-controlled molding ensure that rPET bottles meet the same pressure and top-load standards as virgin bottles.